-

Telephone:+86-13222111178

-

Wechat:gary327252

-

-

Mailbox:postmaster@ermak.cn

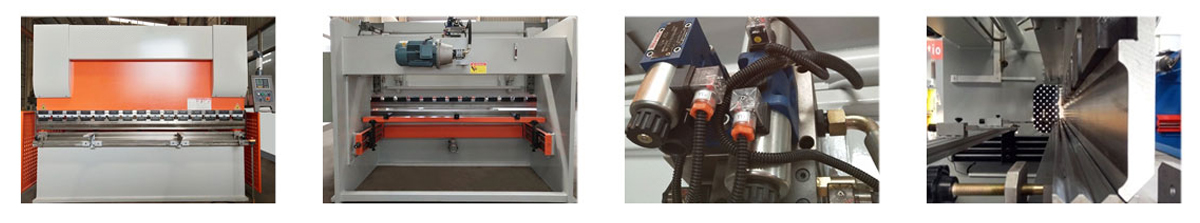

Product details

Performance characteristics

1. Hack gauge and block control. Control for general AC motors, Frequency inverter.

2.Intelligent positioning. stock counter. Holding/decompression time setting.

3.Program memory of up to 40 programs up to 25 steps per program.

4.One side positioning. retract function. one key backup/restore of parameters. mm/inch. English Language operation.

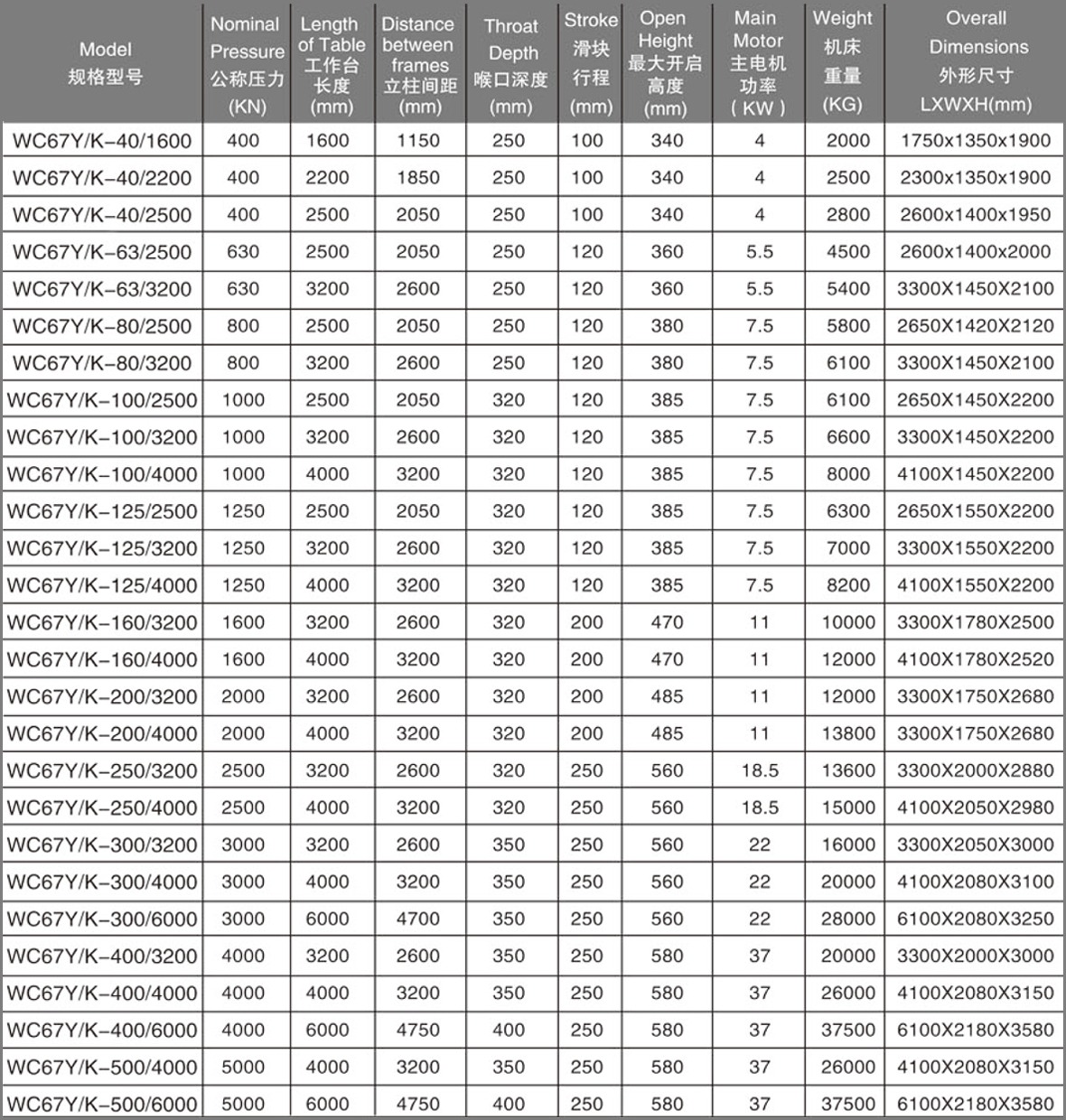

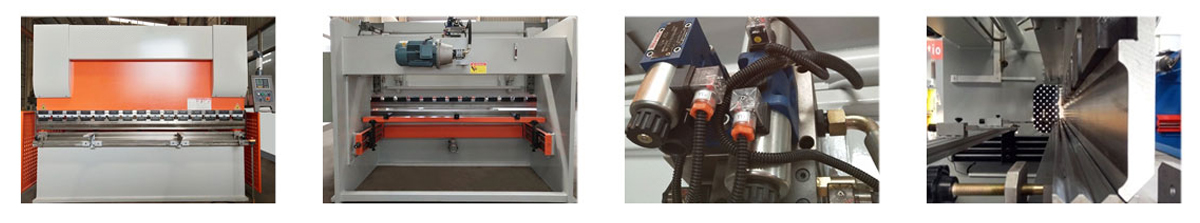

▇ STANDARD EQUIPMENTS √ Height-adjustable and movable sliding front support arm. √ The top and bottom tools are surface hardened by special treatment. √ The Netherlands DELEM E21 NC system can store 24 workpiece programs. √ X-axis Taiwan Shihlin Inverter, stroke 800 mm. Ball screw, timing belt drive. Repeat positioning accuracy ±0.1mm. √ 410 mm throat depth. √ 2 back cover fingers, welded beam, heat treatment process, no deformation for long-term use. √ Metric and inch measurements. √ Foot pedals are produced according to CE standards and are suitable for single and multiple bends. √ Cylinder and top beam cover. √ Pre-adjust electrical requirements based on customer's geographic area.

| ▇ OPTIONAL EQUIPMENTS √ Special strokes and throat depth provide additional advantages for deep bends. √ CNC system E200, E210, E300. √ Special rear cover fingers can be added on the optional backgauge stroke. √ Hydraulic oil heating and cooling. √ Customized table width and bottom tool V opening. √ Optional top and bottom tool lengths are different. √ Box and pole bent special tools. √ Laser avant-garde option. √ WILA top and bottom tool clamping systems. √ Rol 1, 2, 3, 4, 5 different top and bottom quick release clamping systems. √ The tool cabinet is mounted on one side of the machine, keeping the tool clean and easily accessible. √ The automatic sliding system automatically lubricates and it is highly recommended to extend the service life. √ U-shaped special bottom tool for bending thick material. √ Additional front support arms prevent waves on thin materials. √ Customize the machine according to the customer's special parameters. √ According to the customer's requirements, the electrical panel and/or controller can be mounted on the right side of the machine. |

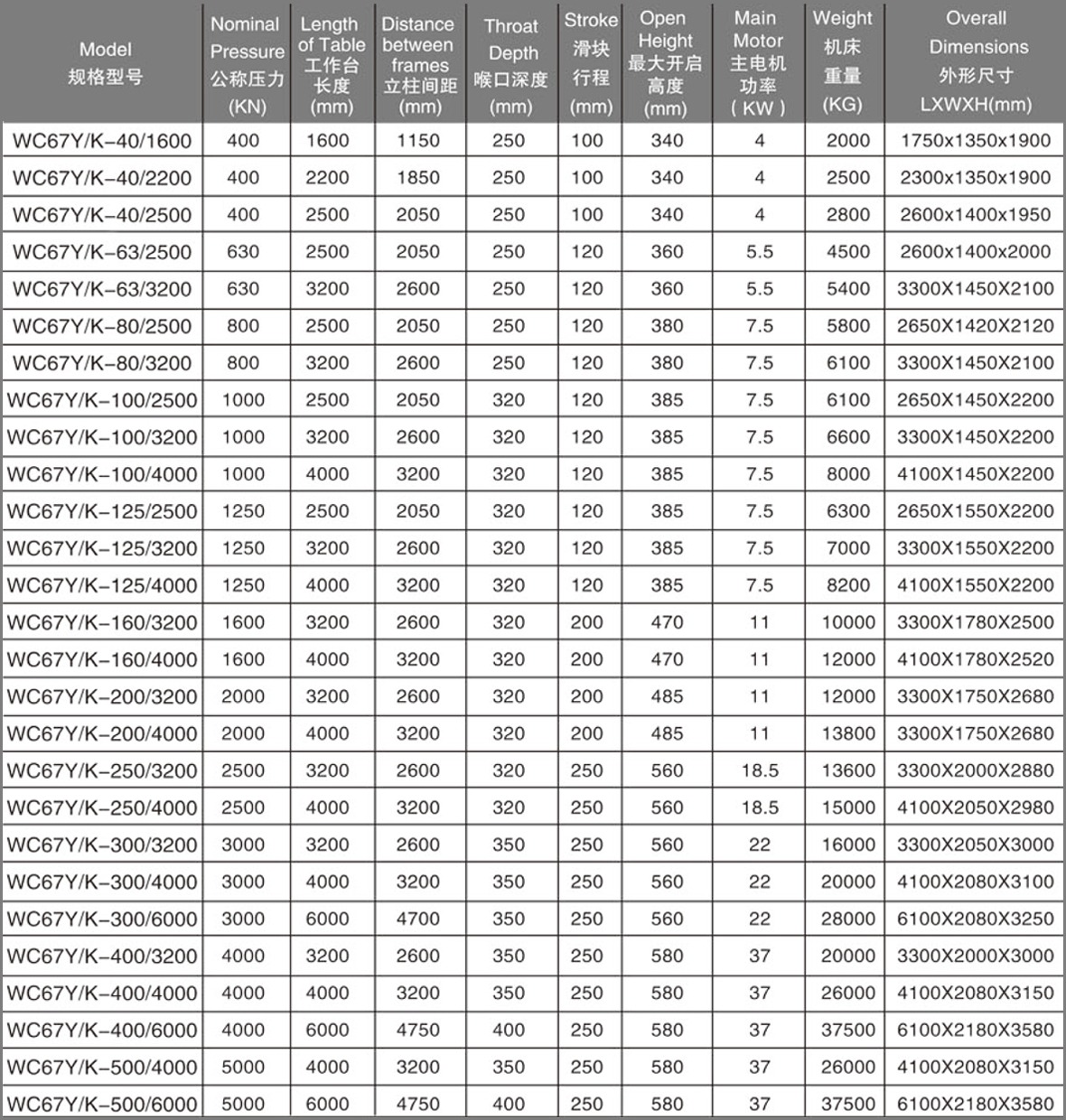

Product parameters

Product details

Performance characteristics

1. Hack gauge and block control. Control for general AC motors, Frequency inverter.

2.Intelligent positioning. stock counter. Holding/decompression time setting.

3.Program memory of up to 40 programs up to 25 steps per program.

4.One side positioning. retract function. one key backup/restore of parameters. mm/inch. English Language operation.

▇ STANDARD EQUIPMENTS √ Height-adjustable and movable sliding front support arm. √ The top and bottom tools are surface hardened by special treatment. √ The Netherlands DELEM E21 NC system can store 24 workpiece programs. √ X-axis Taiwan Shihlin Inverter, stroke 800 mm. Ball screw, timing belt drive. Repeat positioning accuracy ±0.1mm. √ 410 mm throat depth. √ 2 back cover fingers, welded beam, heat treatment process, no deformation for long-term use. √ Metric and inch measurements. √ Foot pedals are produced according to CE standards and are suitable for single and multiple bends. √ Cylinder and top beam cover. √ Pre-adjust electrical requirements based on customer's geographic area.

| ▇ OPTIONAL EQUIPMENTS √ Special strokes and throat depth provide additional advantages for deep bends. √ CNC system E200, E210, E300. √ Special rear cover fingers can be added on the optional backgauge stroke. √ Hydraulic oil heating and cooling. √ Customized table width and bottom tool V opening. √ Optional top and bottom tool lengths are different. √ Box and pole bent special tools. √ Laser avant-garde option. √ WILA top and bottom tool clamping systems. √ Rol 1, 2, 3, 4, 5 different top and bottom quick release clamping systems. √ The tool cabinet is mounted on one side of the machine, keeping the tool clean and easily accessible. √ The automatic sliding system automatically lubricates and it is highly recommended to extend the service life. √ U-shaped special bottom tool for bending thick material. √ Additional front support arms prevent waves on thin materials. √ Customize the machine according to the customer's special parameters. √ According to the customer's requirements, the electrical panel and/or controller can be mounted on the right side of the machine. |

Product parameters