-

Telephone:+86-13222111178

-

Wechat:gary327252

-

-

Mailbox:postmaster@ermak.cn

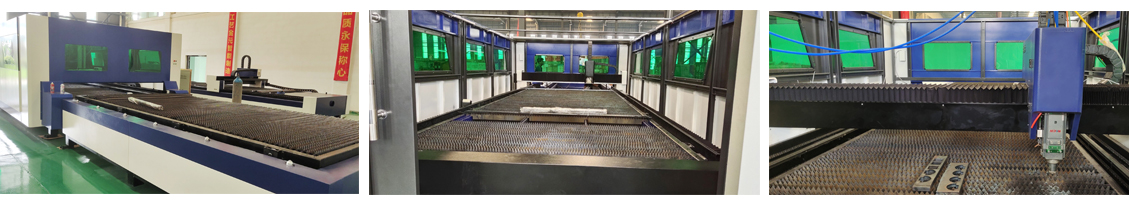

Product details

Applications

Applied materials:special fast cutting various metal plates, pipes (plus pipe cutting device), suitable for stainless steel, low carbon steel, manganese steel, galvanized steel, alloy steel, rare metals and other sheet metal, pipe rapid cutting.

Application industry:widely used in electric power, automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, automotive decoration, sheet metal production, lighting hardware, display equipment, precision parts, hardware products and other industries.

Performance characteristics

1. Lower operation cost,every hour only consumed 0.5W to 1.5W.

2. High performance qualified fiber generator,which is high reliability and longevity of service. Max life reach to more than 100000 hours.

3. Higher cutting speed and efficient,Max cutting speed can be reach 12m/min cutting 1mm mild steel.

4. Free maintenance for fiber laser generator.

5. Smooth cutting surface,little deformation,pretty leveling appearance.

6. Import German ATLANTA rack and pinion,rail from Taiwan Hiwin,servo motor from Japan Yaskawa makes the performance more stable.

7. Dedicated software enables graphic or text into instantly designed pr processed. Flexible and easy operation.

8. The machine full protection with exchange cutting table. Much safe for operator.

▇ Machine configuration Fiber laser generator :Raycus fiber laser Double driver Rack:Germany Atlanta Control software :Cypcut CNC system Optical lens system :U S AⅡⅥ Pneumatic components :Japan SMC、BURKERT Electrical components :Germany Siemens Servo motor:Japan Yaskawa Water chiller :China Tongfei | ▇ Technical parameters Model:SL-3015F Laser generator :China Raycus fiber laser Laser power :3000W Laser wavelength :1070nm Cutting table size :3000mm*1500mm Alarm positioning :Red light instruction Max positioning speed :50m/min X/Y axis positioning accuracy :±0.05mm/m X/Y axis repositioning accuracy :±0.03mm Support graphic format :DXF,PLT,DWG etc Max cutting thickness :Stainless steel : ≤4mm, ,Mild steel : ≤10mm Total power :≤25KW Power supply requirement :3 phase 380V,50Hz,60A Main machine dimension :5020*2750*1650mm |

| ▇ Note |

Fiber laser generator Characteristics: High electro-optical conversion efficiency 、Customized output fiber length 、QBH connector 、Maintenance-free operation 、Wide modulation frequency range 、Small size, easy to instal. |

WSX cutting head Cutting head,which has Z axis follow-up function. Highly sensitive and follow-up cutting head applies capacitance sensor monitoring, offering automatic adjusting function with stable and fast cutting. All kinds of matching design of nozzle are applied to lens with many focuses and can also be equipped with optical lens with different focuses. The focus and nozzle can be adjustable flexibly, including adjusting lens on X-Y direction and nozzles on the same axis. |

Cutting thickness Carbon steel 0.5-10 mm Maximum Auxiliary gas Oxygen ; Stainless steel 0.5-4 mm Maximum Auxiliary gas Nitrogen ; |

Transmission system Each rail installation should be collimator calibration ; The accuracy of splicing at two racks is controlled within 0.01mm |

CNC metal frame Each plate welding machine tool must be fine welding and meticulous grinding.Each steel plate welding machine should be T6 heat treatment to eliminate stress. After each tempering steel welding machine are imported gantry machining center processing.To ensure that the machine straightness and flatness. After installation, the equipment must be calibrated by laser interferometer and precision compensated by American API Company to ensure the walking accuracy and repeatability of the factory equipment. |

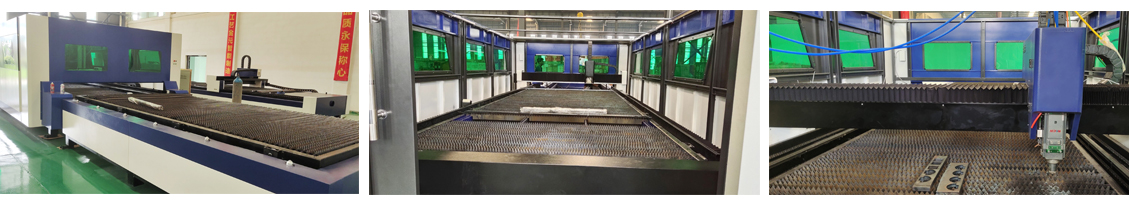

Product details

Applications

Applied materials:special fast cutting various metal plates, pipes (plus pipe cutting device), suitable for stainless steel, low carbon steel, manganese steel, galvanized steel, alloy steel, rare metals and other sheet metal, pipe rapid cutting.

Application industry:widely used in electric power, automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, automotive decoration, sheet metal production, lighting hardware, display equipment, precision parts, hardware products and other industries.

Performance characteristics

1. Lower operation cost,every hour only consumed 0.5W to 1.5W.

2. High performance qualified fiber generator,which is high reliability and longevity of service. Max life reach to more than 100000 hours.

3. Higher cutting speed and efficient,Max cutting speed can be reach 12m/min cutting 1mm mild steel.

4. Free maintenance for fiber laser generator.

5. Smooth cutting surface,little deformation,pretty leveling appearance.

6. Import German ATLANTA rack and pinion,rail from Taiwan Hiwin,servo motor from Japan Yaskawa makes the performance more stable.

7. Dedicated software enables graphic or text into instantly designed pr processed. Flexible and easy operation.

8. The machine full protection with exchange cutting table. Much safe for operator.

▇ Machine configuration Fiber laser generator :Raycus fiber laser Double driver Rack:Germany Atlanta Control software :Cypcut CNC system Optical lens system :U S AⅡⅥ Pneumatic components :Japan SMC、BURKERT Electrical components :Germany Siemens Servo motor:Japan Yaskawa Water chiller :China Tongfei | ▇ Technical parameters Model:SL-3015F Laser generator :China Raycus fiber laser Laser power :3000W Laser wavelength :1070nm Cutting table size :3000mm*1500mm Alarm positioning :Red light instruction Max positioning speed :50m/min X/Y axis positioning accuracy :±0.05mm/m X/Y axis repositioning accuracy :±0.03mm Support graphic format :DXF,PLT,DWG etc Max cutting thickness :Stainless steel : ≤4mm, ,Mild steel : ≤10mm Total power :≤25KW Power supply requirement :3 phase 380V,50Hz,60A Main machine dimension :5020*2750*1650mm |

| ▇ Note |

Fiber laser generator Characteristics: High electro-optical conversion efficiency 、Customized output fiber length 、QBH connector 、Maintenance-free operation 、Wide modulation frequency range 、Small size, easy to instal. |

WSX cutting head Cutting head,which has Z axis follow-up function. Highly sensitive and follow-up cutting head applies capacitance sensor monitoring, offering automatic adjusting function with stable and fast cutting. All kinds of matching design of nozzle are applied to lens with many focuses and can also be equipped with optical lens with different focuses. The focus and nozzle can be adjustable flexibly, including adjusting lens on X-Y direction and nozzles on the same axis. |

Cutting thickness Carbon steel 0.5-10 mm Maximum Auxiliary gas Oxygen ; Stainless steel 0.5-4 mm Maximum Auxiliary gas Nitrogen ; |

Transmission system Each rail installation should be collimator calibration ; The accuracy of splicing at two racks is controlled within 0.01mm |

CNC metal frame Each plate welding machine tool must be fine welding and meticulous grinding.Each steel plate welding machine should be T6 heat treatment to eliminate stress. After each tempering steel welding machine are imported gantry machining center processing.To ensure that the machine straightness and flatness. After installation, the equipment must be calibrated by laser interferometer and precision compensated by American API Company to ensure the walking accuracy and repeatability of the factory equipment. |