-

Telephone:+86-13222111178

-

Wechat:gary327252

-

-

Mailbox:postmaster@ermak.cn

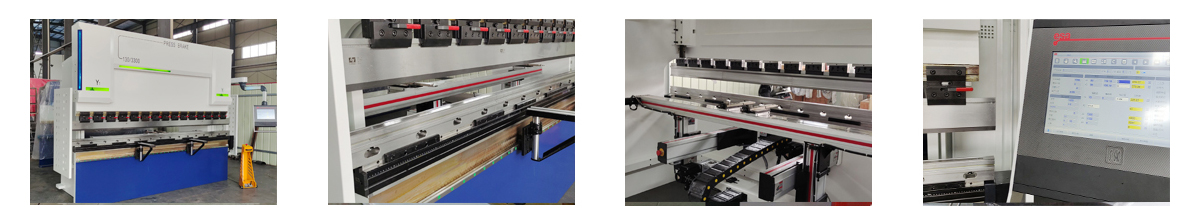

Product details

Performance characteristics

▪ Integral welding processing structure

▪ International famous brand electro-hydraulic servo valve and grating ruler form closed loop control mode

▪ High slider position feedback accuracy, accurate and smooth operation, good synchronization performance, bending accuracy, high slider repeat positioning accuracy.

▪ Rear baffle material can be according to customer demand to adopt more complete function of the rear baffle material shaft of the rear baffle material mechanism.

▪ The hydraulic system adopts integrated control system, which reduces the installation of pipelines, eliminates oil leakage, ensures the working stability of machine tools, and makes the appearance scientific and beautiful.

▪ Hydraulic deflection automatic compensation mechanism, eliminate the impact of slider deformation on the quality of the workpiece, CNC system automatically adjust the amount of compensation, easy and accurate operation.

▪ CNC system using the Netherlands DELEM, Italy ESA, Switzerland CYBELEC and other well-known brands dedicated CNC bending machine system.

Standard configuration specification:

▪ Hydraulic system: BOSCH, Germany

▪ Servo motor and drive: nanjing easton

▪ Grating ruler: HEIDENHAIN, Germany, GIVI, Italy

▪ Ball screw and linear guide: HIWIN, Taiwan

▪ Main electrical components: French SCHNEIDER

▪ Bench compensation: hydraulic compensation or mechanical compensation

▪ Simple adjustable pre-moving bracket with guide rail

Working principle of hydraulic deflection compensation mechanism

In the process of bending, the Angle of the bending workpiece is inconsistent due to the certain amount of deformation between the slider and the workpiece, especially the hot-rolled plate of stainless steel, which has large rebound force and large error.This series bending machine adopts the workbench hydraulic automatic deflection compensation mechanism, it is composed of a set of oil cylinder installed in the workbench, and each compensation location of the oil cylinder, size is according to the slider, finite element analysis of the deflection curve design compensation table, hydraulic compensation is after the former three vertical plate, the relative displacement between the neutral version of the convex compensation, to achieve its principle is accomplished by elastic deformation of steel itself raised, so the amount of compensation can be realized within the elastic range in the workbench.

Product parameters

| Model | Nominal Pressure (kn) | Length of table (mm) | Distance Between Housing (mm) | Throat Depth (mm) | Stroke (mm) | Open Hight(mm) | Main Motor (kw) | Dimensions (L × W × H)(mm) |

| 40/2000 | 400 | 2000 | 1600 | 200 | 110 | 335 | 4 | 2545×1510×2050 |

| 40/2500 | 400 | 2500 | 2000 | 200 | 110 | 335 | 4 | 2950×1510×2080 |

| 63/2000 | 630 | 2000 | 1600 | 250 | 110 | 350 | 5.5 | 2555×1600×2130 |

| 63/2500 | 630 | 2500 | 2000 | 250 | 110 | 350 | 5.5 | 2960×1600×2180 |

| 63/3200 | 630 | 3200 | 2600 | 250 | 110 | 350 | 5.5 | 3740×1600×2230 |

| 100/2500 | 1000 | 2500 | 2000 | 350 | 150 | 400 | 7.5 | 2980×1650×2330 |

| 100/3200 | 1000 | 3200 | 2600 | 350 | 150 | 400 | 7.5 | 3740×1650×2355 |

| 100/4000 | 1000 | 4000 | 3200 | 350 | 150 | 400 | 7.5 | 4550×1650×2450 |

| 100/5000 | 1000 | 5000 | 4000 | 350 | 150 | 400 | 7.5 | 5100×1500×2650 |

| 125/2500 | 1250 | 2500 | 2000 | 350 | 150 | 410 | 7.5 | 3980×1650×2370 |

| 125/3200 | 1250 | 3200 | 2600 | 350 | 150 | 410 | 7.5 | 3750×1650×2450 |

| 125/4000 | 1250 | 4000 | 3200 | 350 | 150 | 410 | 7.5 | 4550×1650×2470 |

| 125/5000 | 1250 | 5000 | 4000 | 350 | 150 | 410 | 7.5 | 5100×1500×2795 |

| 125/6000 | 1250 | 6000 | 4500 | 350 | 150 | 410 | 7.5 | 6100×1500×2895 |

| 160/2500 | 1600 | 2500 | 2000 | 350 | 150 | 425 | 11 | 2980×1715×2410 |

| 160/3200 | 1600 | 3200 | 2550 | 350 | 150 | 425 | 11 | 3750×1715×2450 |

| 160/4000 | 1600 | 4000 | 3200 | 350 | 190 | 450 | 11 | 4550×1715×2730 |

| 160/5000 | 1600 | 5000 | 4000 | 350 | 190 | 450 | 11 | 5100×1570×2900 |

| 160/6000 | 1600 | 6000 | 4500 | 350 | 190 | 450 | 11 | 6100×1570×3010 |

| 200/3200 | 2000 | 3200 | 2600 | 350 | 240 | 460 | 11 | 3750×1815×2715 |

| 200/4000 | 2000 | 4000 | 3200 | 350 | 240 | 460 | 11 | 4550×1815×2850 |

| 200/5000 | 2000 | 5000 | 3800 | 350 | 240 | 460 | 11 | 5100×1715×3020 |

| 200/6000 | 2000 | 6000 | 4500 | 350 | 240 | 460 | 11 | 6100×1715×3120 |

| 250/3200 | 2500 | 3200 | 2600 | 400 | 240 | 525 | 11 | 3750×2010×2850 |

| 250/4000 | 2500 | 4000 | 3200 | 400 | 240 | 525 | 11 | 4550×2010×3010 |

| 250/5000 | 2500 | 5000 | 3800 | 400 | 240 | 525 | 11 | 5100×1890×3190 |

| 250/6000 | 2500 | 6000 | 4500 | 400 | 240 | 525 | 11 | 6100×1890×3350 |

| 300/3200 | 3000 | 3200 | 2600 | 400 | 250 | 545 | 15 | 3740×2100×3235 |

Product details

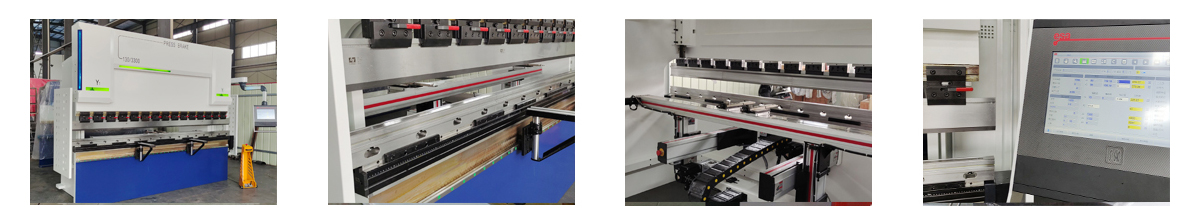

Performance characteristics

▪ Integral welding processing structure

▪ International famous brand electro-hydraulic servo valve and grating ruler form closed loop control mode

▪ High slider position feedback accuracy, accurate and smooth operation, good synchronization performance, bending accuracy, high slider repeat positioning accuracy.

▪ Rear baffle material can be according to customer demand to adopt more complete function of the rear baffle material shaft of the rear baffle material mechanism.

▪ The hydraulic system adopts integrated control system, which reduces the installation of pipelines, eliminates oil leakage, ensures the working stability of machine tools, and makes the appearance scientific and beautiful.

▪ Hydraulic deflection automatic compensation mechanism, eliminate the impact of slider deformation on the quality of the workpiece, CNC system automatically adjust the amount of compensation, easy and accurate operation.

▪ CNC system using the Netherlands DELEM, Italy ESA, Switzerland CYBELEC and other well-known brands dedicated CNC bending machine system.

Standard configuration specification:

▪ Hydraulic system: BOSCH, Germany

▪ Servo motor and drive: nanjing easton

▪ Grating ruler: HEIDENHAIN, Germany, GIVI, Italy

▪ Ball screw and linear guide: HIWIN, Taiwan

▪ Main electrical components: French SCHNEIDER

▪ Bench compensation: hydraulic compensation or mechanical compensation

▪ Simple adjustable pre-moving bracket with guide rail

Working principle of hydraulic deflection compensation mechanism

In the process of bending, the Angle of the bending workpiece is inconsistent due to the certain amount of deformation between the slider and the workpiece, especially the hot-rolled plate of stainless steel, which has large rebound force and large error.This series bending machine adopts the workbench hydraulic automatic deflection compensation mechanism, it is composed of a set of oil cylinder installed in the workbench, and each compensation location of the oil cylinder, size is according to the slider, finite element analysis of the deflection curve design compensation table, hydraulic compensation is after the former three vertical plate, the relative displacement between the neutral version of the convex compensation, to achieve its principle is accomplished by elastic deformation of steel itself raised, so the amount of compensation can be realized within the elastic range in the workbench.

Product parameters

| Model | Nominal Pressure (kn) | Length of table (mm) | Distance Between Housing (mm) | Throat Depth (mm) | Stroke (mm) | Open Hight(mm) | Main Motor (kw) | Dimensions (L × W × H)(mm) |

| 40/2000 | 400 | 2000 | 1600 | 200 | 110 | 335 | 4 | 2545×1510×2050 |

| 40/2500 | 400 | 2500 | 2000 | 200 | 110 | 335 | 4 | 2950×1510×2080 |

| 63/2000 | 630 | 2000 | 1600 | 250 | 110 | 350 | 5.5 | 2555×1600×2130 |

| 63/2500 | 630 | 2500 | 2000 | 250 | 110 | 350 | 5.5 | 2960×1600×2180 |

| 63/3200 | 630 | 3200 | 2600 | 250 | 110 | 350 | 5.5 | 3740×1600×2230 |

| 100/2500 | 1000 | 2500 | 2000 | 350 | 150 | 400 | 7.5 | 2980×1650×2330 |

| 100/3200 | 1000 | 3200 | 2600 | 350 | 150 | 400 | 7.5 | 3740×1650×2355 |

| 100/4000 | 1000 | 4000 | 3200 | 350 | 150 | 400 | 7.5 | 4550×1650×2450 |

| 100/5000 | 1000 | 5000 | 4000 | 350 | 150 | 400 | 7.5 | 5100×1500×2650 |

| 125/2500 | 1250 | 2500 | 2000 | 350 | 150 | 410 | 7.5 | 3980×1650×2370 |

| 125/3200 | 1250 | 3200 | 2600 | 350 | 150 | 410 | 7.5 | 3750×1650×2450 |

| 125/4000 | 1250 | 4000 | 3200 | 350 | 150 | 410 | 7.5 | 4550×1650×2470 |

| 125/5000 | 1250 | 5000 | 4000 | 350 | 150 | 410 | 7.5 | 5100×1500×2795 |

| 125/6000 | 1250 | 6000 | 4500 | 350 | 150 | 410 | 7.5 | 6100×1500×2895 |

| 160/2500 | 1600 | 2500 | 2000 | 350 | 150 | 425 | 11 | 2980×1715×2410 |

| 160/3200 | 1600 | 3200 | 2550 | 350 | 150 | 425 | 11 | 3750×1715×2450 |

| 160/4000 | 1600 | 4000 | 3200 | 350 | 190 | 450 | 11 | 4550×1715×2730 |

| 160/5000 | 1600 | 5000 | 4000 | 350 | 190 | 450 | 11 | 5100×1570×2900 |

| 160/6000 | 1600 | 6000 | 4500 | 350 | 190 | 450 | 11 | 6100×1570×3010 |

| 200/3200 | 2000 | 3200 | 2600 | 350 | 240 | 460 | 11 | 3750×1815×2715 |

| 200/4000 | 2000 | 4000 | 3200 | 350 | 240 | 460 | 11 | 4550×1815×2850 |

| 200/5000 | 2000 | 5000 | 3800 | 350 | 240 | 460 | 11 | 5100×1715×3020 |

| 200/6000 | 2000 | 6000 | 4500 | 350 | 240 | 460 | 11 | 6100×1715×3120 |

| 250/3200 | 2500 | 3200 | 2600 | 400 | 240 | 525 | 11 | 3750×2010×2850 |

| 250/4000 | 2500 | 4000 | 3200 | 400 | 240 | 525 | 11 | 4550×2010×3010 |

| 250/5000 | 2500 | 5000 | 3800 | 400 | 240 | 525 | 11 | 5100×1890×3190 |

| 250/6000 | 2500 | 6000 | 4500 | 400 | 240 | 525 | 11 | 6100×1890×3350 |

| 300/3200 | 3000 | 3200 | 2600 | 400 | 250 | 545 | 15 | 3740×2100×3235 |