-

Telephone:+86-13222111178

-

Wechat:gary327252

-

-

Mailbox:postmaster@ermak.cn

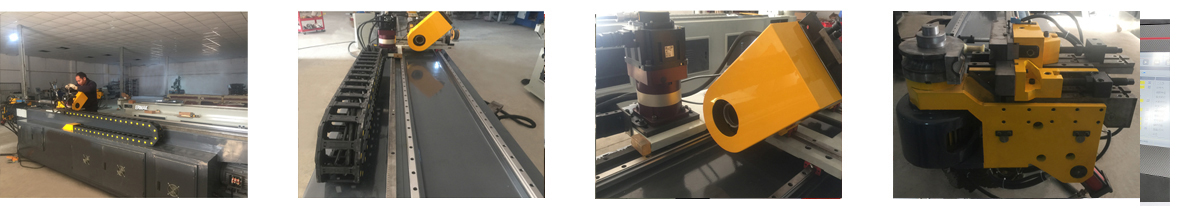

Product details

Performance characteristics

1. Bend-arm (C-axis) by hydraulic. Clamp die by hydraulic, Pressure die by hydraulic.

2. Carriage (Y-axis) by servo motor. Collet (B-axis) : rotation by servo motor, grip by hydraulic.

3. Anticipated mandrel retraction unit. Standing pedestal, serves emergency stop and remote control.

4. Fan-cooling system. Diagnosis error immediately.

5. Central Automatic lubrication system.

6. Foot pedal for safe start.

7. It is fully automatic pipe bending machine, with PLC control system, two servo for rotary, feeding.

8. Touch screen panel display English, have different bending degree prefabricate, dialogue operation, can choose manual,semi-automatic and full automatic operation manual, portable pedal switch with start and emergency stop function.Multi axes working simultaneously.

9. Bending pipe — Automatic. Rotating pipe — Automatic. Feeding pipe — Automatic.

10. One key back up of programs for USB or disk storage or through INTERNET. Management and storage of bend data and tools is done in standard text files on the hard disk of the control PLC. In case of requirement it is also possible to integrate the PLC into bending machine. Therefore an Ethernet adapter is included. The number of tools and products is practically unlimited. Product and tool files can easily be edited (also on a separate PLC) and printed out.

11. Security code for the protection the data setting and selected operation features.

12. To access to the history bending setting data to the facilitate study of malfunction with one set of tooling.

13. All the parts of hydraulic system, control system, driver system and display system are imported from famous brand, with high accuracy, high efficient, suitable for mass production.

14. CNC fully auto, have cubical space bending equipment, loading the whole bending process is automatic.

15. The machine is convenient operation, stable performance and high safety factor. The machine is the ideal choice for the pipe processing.

Product parameters

| Main Technical Parameter | Unit | 18CNC | 28CNC | 38CNC | 50CNC | 63CNC | 76CNC | 89CNC | 114CNC | 129CNC | 140CNC |

| Max. Bending Capacity | mm | 18×2 | 28×2 | 38×2 | 50×2 | 63×4 | 76×5 | 89×6 | 114×8 | 129×8 | 140×10 |

| Bending Radius Region | mm | 3-150 | 5-180 | 10-200 | 15-250 | 20-300 | 25-350 | 40-450 | 40-550 | 50-650 | 50-650 |

| Bending Angle Region | Degree | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° |

Effective Length Over Mandrel | mm | 1500 | 2800 | 3200 | 3500 | 4000 | 4200 | 4600 | 4800 | 5200 | 5800 |

| Oil Pressure System Motor | kw | 2.2 | 2.2 | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Max. Pressure | kg/cm | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

| Machine Dimension | mm | 3000×700 ×1300 | 3500×750 ×1300 | 4200×950 ×1350 | 4800×1000 ×1350 | 5200×1100 ×1350 | 5800×1200 ×1350 | 6200×1500 ×1350 | 6800×1650 ×1350 | 7200×1800 ×1350 | 7500×1850 ×1550 |

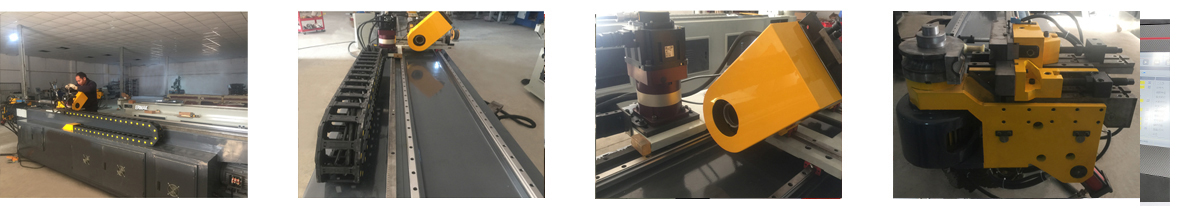

Product details

Performance characteristics

1. Bend-arm (C-axis) by hydraulic. Clamp die by hydraulic, Pressure die by hydraulic.

2. Carriage (Y-axis) by servo motor. Collet (B-axis) : rotation by servo motor, grip by hydraulic.

3. Anticipated mandrel retraction unit. Standing pedestal, serves emergency stop and remote control.

4. Fan-cooling system. Diagnosis error immediately.

5. Central Automatic lubrication system.

6. Foot pedal for safe start.

7. It is fully automatic pipe bending machine, with PLC control system, two servo for rotary, feeding.

8. Touch screen panel display English, have different bending degree prefabricate, dialogue operation, can choose manual,semi-automatic and full automatic operation manual, portable pedal switch with start and emergency stop function.Multi axes working simultaneously.

9. Bending pipe — Automatic. Rotating pipe — Automatic. Feeding pipe — Automatic.

10. One key back up of programs for USB or disk storage or through INTERNET. Management and storage of bend data and tools is done in standard text files on the hard disk of the control PLC. In case of requirement it is also possible to integrate the PLC into bending machine. Therefore an Ethernet adapter is included. The number of tools and products is practically unlimited. Product and tool files can easily be edited (also on a separate PLC) and printed out.

11. Security code for the protection the data setting and selected operation features.

12. To access to the history bending setting data to the facilitate study of malfunction with one set of tooling.

13. All the parts of hydraulic system, control system, driver system and display system are imported from famous brand, with high accuracy, high efficient, suitable for mass production.

14. CNC fully auto, have cubical space bending equipment, loading the whole bending process is automatic.

15. The machine is convenient operation, stable performance and high safety factor. The machine is the ideal choice for the pipe processing.

Product parameters

| Main Technical Parameter | Unit | 18CNC | 28CNC | 38CNC | 50CNC | 63CNC | 76CNC | 89CNC | 114CNC | 129CNC | 140CNC |

| Max. Bending Capacity | mm | 18×2 | 28×2 | 38×2 | 50×2 | 63×4 | 76×5 | 89×6 | 114×8 | 129×8 | 140×10 |

| Bending Radius Region | mm | 3-150 | 5-180 | 10-200 | 15-250 | 20-300 | 25-350 | 40-450 | 40-550 | 50-650 | 50-650 |

| Bending Angle Region | Degree | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° | 0-190° |

Effective Length Over Mandrel | mm | 1500 | 2800 | 3200 | 3500 | 4000 | 4200 | 4600 | 4800 | 5200 | 5800 |

| Oil Pressure System Motor | kw | 2.2 | 2.2 | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Max. Pressure | kg/cm | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

| Machine Dimension | mm | 3000×700 ×1300 | 3500×750 ×1300 | 4200×950 ×1350 | 4800×1000 ×1350 | 5200×1100 ×1350 | 5800×1200 ×1350 | 6200×1500 ×1350 | 6800×1650 ×1350 | 7200×1800 ×1350 | 7500×1850 ×1550 |